This post provides an overview of the robot presented for the Mobile Robotics subject. This robot was originally developed for the Olimpic Robotic Challenge promoted by Makers UPV.

Mechanical design

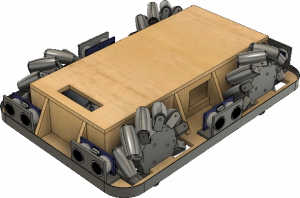

The robot is holonomic, meaning that each of its degrees of freedom can be controlled directly. It is capable of moving around on the XY plane without the need to rotate, but it can do so around the Z axis when controlled in diferential mode.

The robot is designed and built completely from the ground up, using many kinds of materials: wood, metal, plastic and elastomers. Although only some parts of the wheels were designed using a CAD software (Fusión360), the rest of the robot was modeled for the course.

Bodywork

The robot’s main body is made of 5mm plywood manually cut and glued using wood glue. It is a light yet a sturdy design that holds al the electronics securerly inside. As the robot could get hit, a metal bumper made from a metal strip was added around its perimeter.

Wheels

Perhaps, the most interesting part of the robot. Although there are commercially available solutions, they can be quite expensive, therefore it was decided to make them from scratch. The wheel structure also combines several materials. The hub and the core of the rollers are 3D printed. The rollers are coverd with a silicone tube and fixed to the hub using metal brakets (made from the same material as the bumper). This sub assembly is connected through a metal plate to a coupler made from aluminium that it self is secured to the motor shafts.

Electronics

The robot is powered with a 12 volt lithium (LIPO) battery. These 12 volts are used directly to drive the direct current motors via a double H bridge (L298N) and on the other hand they are lowered to 5 volts to power the rest of the elecontrics. To step down from 12 volts to 5 volts a commuted voltage regulator is used. The output of the regulator is connected to an Arduino Mega 2560 to which other accessories are plugged.

There are 5 infrared sensors located underneath the robot used to follow lines and detect marks in the ground. Another 4 sensors of the same kind are used as encoders to obtain the speed of each wheel. The robot also includes 6 ultrasound sensors to detect objects around it.

Apart from the internal control algorithms, the robot can also be controlled with a PlayStation 2 remote control with an RF receiver or via bluetooth with its At-09 transceiver.

Para el control del robot, además de los algoritmos internos, se pueden emplear dos medios inalámbricos: un mando de PlayStation 2 con un receptor RF y un transceptor bluetooth AT-09.

Programming

The robot was programmed using the Arduino IDE. Only one piece of code was developed which allows the selection of different operation modes. Eventhough the robot has many sensors, in this case only one infrarred one was used for the line following mode.

Mobile app

To make use of the bluetooth transceiver, a mobile app was developed using the Thunkable plaftorm. From the app any operation mode can be selected and it is even possible to directly control the robot from the smartphone based on the internal gyroscope.

To sum up, it is a robot with many possiblities, but due to the limited time available during the course only a simple application was developed. There are plans to develop a more complex application to take advantage of all the sensors and actuators.